Building a durable Bluetooth speaker starts with choosing the right materials. The best materials for building a durable Bluetooth speaker include metals (like aluminum or steel), dense woods (e.g. birch plywood), impact-resistant plastics (ABS, polycarbonate) and flexible rubbers or silicones for sealing. These materials resist drops, moisture, and wear while improving sound quality For example, ABS plastic “offers strength, toughness, and durability,” making it a common choice for rugged speaker enclosures In practice, many manufacturers also combine materials – such as an aluminum housing with rubber bumpers – to maximize toughness.

Key Durable Materials:

- Metals (Aluminum/Steel): Rigid, impact-resistant chassis, corrosion-resistant.

- Wood (Plywood/MDF): Stiff, dense cabinets (e.g. void-free Baltic Birch plywood for high-quality enclosures

- High-Impact Plastics (ABS/Polycarbonate/Polypropylene): Lightweight, tough housings

- Rubber/Silicone (NBR, Santoprene, silicone): Shock-absorbing bumpers and weather seals

- Composite Fibers (Kevlar/Carbon Fiber): Very strong, used in speaker cones or enclosures for extra rigidityblog.miscospeakers.com.

The selection above answers “Best materials for building a durable Bluetooth speaker” directly. We will explore each category in detail below.

Table of Contents

- Durable Enclosure Materials

- Metal Enclosures (Aluminum, Steel)

- Wooden Enclosures (Plywood, MDF)

- Plastic Enclosures (ABS, Polycarbonate)

- Robust Speaker Components

- Speaker Cones (Kevlar, Aluminum, Polypropylene)

- Magnets and Wiring

- Waterproofing and Shock Protection

- Ingress Protection (IP) Rating

- Rubber Seals and Shock Absorption

- Conclusion: Best Material Mix

- FAQ

Durable Enclosure Materials

Metal Enclosures (Aluminum, Steel)

Benefits: Metal enclosures are rigid (minimizing unwanted vibration) and can be precision-machined for tight tolerances. They can also be waterproofed easily with proper seal gaskets. However, metal cases tend to cost more and must be engineered to avoid rattling. Many designs use internal rubber mounts for the speaker driver to decouple it from the hard shell.

Wooden Enclosures (Plywood, MDF)

Durability: When properly sealed and finished, wooden cabinets are very durable. Outdoors or on the road, real wood can withstand knocks better than cheap particle board. It can be laminated or coated with hard varnish to resist scratches and moisture. The downside is wood can dent or crack under severe impact. Transition: For added durability, many builders add rubber edges or metal corner guards to wooden enclosures.

Plastic Enclosures (ABS, Polycarbonate)

Advantages: Plastic can be injection-molded into complex shapes (like integrated handles or grills). It also does not splinter or corrode. However, plastic can crack under extreme force, so thick walls or internal ribs are used. Many rugged speakers combine plastic with internal metal frames or with rubber bumpers molded on top. Transition: Because plastics naturally damp vibration, they can help reduce internal reflections, but designers often add internal bracing or foam to improve acoustics.

Other Enclosure Materials

Besides metal, wood, and plastic, some premium designs use composite materials. Examples include fiberglass, carbon fiber, or coated fabrics. Carbon fiber and fiberglass panels are extremely stiff and light, but costly. Some eco-friendly speakers use bamboo wood or hemp fiber composites. In all cases, the principle is the same: use a material that is stiff, dense and consistent to avoid coloration of sound

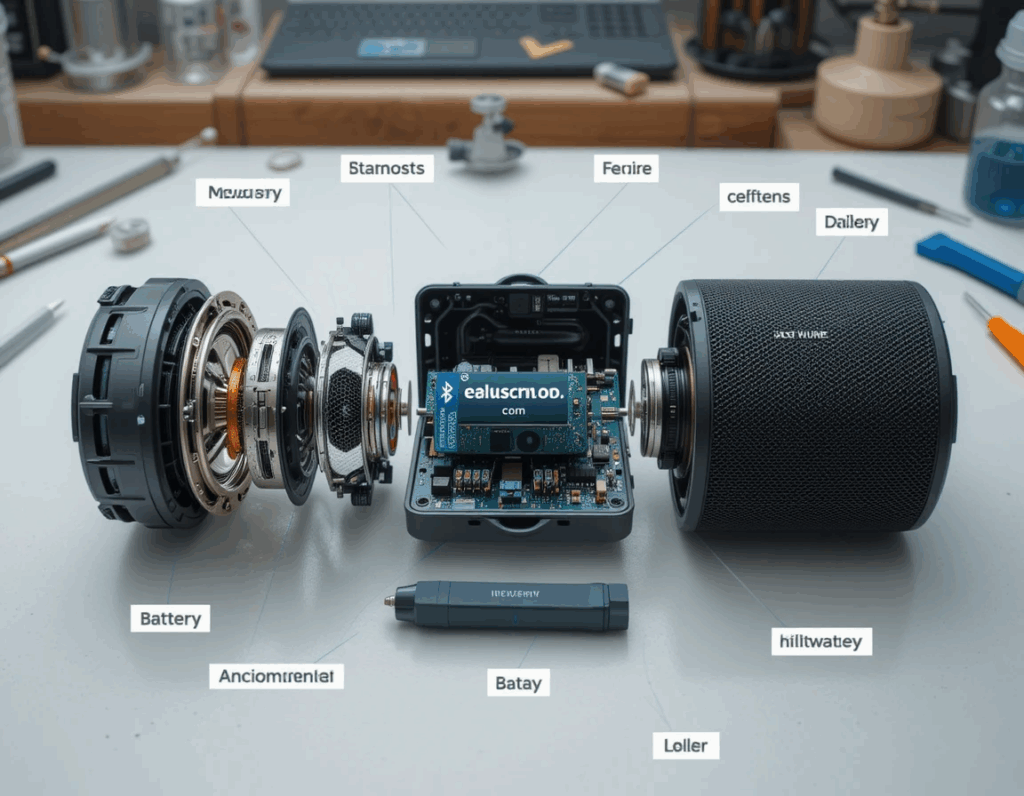

Robust Speaker Components

The enclosure protects the speaker electronics, but the internal components also need durability.

Speaker Cones (Kevlar, Aluminum, Polypropylene)

Speaker cones produce sound and must flex rapidly. For rugged speakers, durable cone materials are chosen. Traditional cones use paper (which can deform with moisture). For durability, manufacturers use materials like Kevlar, Nomex, aluminum, or polypropylene Kevlar (an aramid fiber) is especially tough and cut-resistant – ideal for outdoor speakers Polypropylene cones are common in waterproof speakers because the plastic is water-resistant. Transition: A speaker with a Kevlar cone and rubber surround can achieve high IP ratings (waterproofing) without sacrificing strength.

Many high-performance Bluetooth speakers use aluminum or coated aluminum cones. Aluminum is rigid and non-flexing, giving clear sound. MISCO notes that an all-aluminum cone with a rubber surround can meet IP67 (submersion proof) in the right enclosure In short, for durability:

- Nomex/Kevlar – fibers that are tough, heat-resistant and waterproof.

- Polypropylene – inexpensive, moldable, good moisture resistance.

- Aluminum – metal cone that is dents-resistant and waterproof

Magnets and Wiring

The speaker’s magnet holds the voice coil. Two common magnets are ferrite (ceramic) and neodymium. Ferrite magnets are very stable at high temperature and cheap, but are larger. Neodymium magnets are smaller (lighter speaker) and strong, but they lose strength above ~80°C For a rugged design, either works if kept cool by metal casing.

The voice coil windings are almost always copper (resists heat better than aluminum) The coil bobbin (the cylinder the wire is wound on) can be paper (cheap), aluminum or fiberglass. High-end drivers use Kapton or fiberglass bobbins to handle extreme heatThis may be overkill for a Bluetooth speaker, but shows the range of durable options. Transition: The key point is using materials that don’t degrade under high power or heat, ensuring long-term reliability.

Surrounds and Suspension

The flexible surround (edge of the cone) and spider (suspension) can be made of rubber or treated cloth. For durability in all conditions, Santoprene (a type of vulcanized polymer) and NBR (nitrile butadiene rubber) are excellent choices. Both resist water, oil, and extreme temperatures. Santoprene is often used in waterproof speakers, while NBR is used in many pro drivers. These elastomers keep dust and water out and spring back even after heavy use.

Waterproofing and Shock Protection

Building a durable speaker means it should survive rain, drops, and dust.

Ingress Protection (IP) Rating

An IP rating (Ingress Protection) tells you how well the speaker is sealed. The first digit (0–6) rates dust resistance, the second (0–8) rates water protection. For example, an IP67 speaker is dust-tight and can be submerged in 1m of water. MISCO explains that IP codes are “certified ruggedness levels” for dust and water protection. Outdoor or travel speakers often aim for IPX5 or higher (splash/water resistant) or full IP67/68.

To achieve these, designers use gaskets, o-rings, and sealed seams. All openings (USB ports, speaker grills) get rubber covers or mesh filters. Circuit boards are often coated with conformal coating to resist moisture. Durable materials like silicone and rubber (see below) are critical for sealing gaps without adding weight. Transition: In practice, even simple materials like silicone adhesive or foam seals can greatly improve resistance to rain and sweat.

Rubber Seals and Shock Absorption

Rubber and silicone are used not only for waterproofing but also for shock protection. Rubber bumpers and feet around the casing absorb impact if the speaker is dropped. Silicone covers (common on portable speakers) cushion the edges and rebound after impacts. For example, many rugged models have a rubberized exterior or thick rubber surrounds for the drivers to help them withstand knocks.

From [35] above, we see a close-up of electronics being soldered. A robust speaker often has reinforced solder joints and glue to keep parts in place under vibration. Critical chips (like Bluetooth modules) might be potting-epoxied or coated. Santoprene surrounds (a rubbery polymer) and molded rubber cases can significantly extend lifespan in harsh use . The goal is that the speaker can bounce or tumble without its components breaking loose.

Conclusion: Best Material Mix

In summary, the best materials for building a durable Bluetooth speaker are a combination of:

- A metal or thick plastic chassis to resist impact (aluminum or ABS).

- A stiff wood or composite enclosure for acoustic performance (or reinforced plastic if weight is a concern).

- Rubber/silicone gaskets and bumpers for shock absorption and sealing.

- High-quality driver materials (Kevlar or aluminum cones, rubber surrounds) for long life.

By selecting metals, polymers, elastomers, and composites wisely, manufacturers ensure speakers “withstand humidity, dust, and vibration Proper sealing (meeting a solid IP rating then makes them truly outdoor-ready. The exact mix depends on budget and purpose, but every durable speaker uses at least some combination of these long-lasting materials.

FAQ

Q: What materials make a speaker more durable?

A: Using metal (like aluminum) or thick ABS plastic for the outer case improves toughness. Dense woods like birch plywood or MDF give rigidity. Rubber/silicone parts (bumpers, seals, speaker surrounds) absorb shock and moisture. Also, speaker cones made of Kevlar, aluminum, or coated paper resist damage. In short, a mix of sturdy rigid materials and flexible seals yields a durable speaker

Q: Is metal better than plastic for a speaker enclosure?

A: Metal (aluminum/steel) is more impact-resistant and rigid, but heavier. Plastic (ABS/PC) is lightweight and still very tough when thick. Both can work: many designs use a metal frame with plastic panels or vice versa. The choice depends on weight, cost, and aesthetic. Either way, focus on quality. For example, aviation-grade aluminum or high-grade ABS will last a long time

Q: How do I make my Bluetooth speaker waterproof?

A: You need seals (rubber/silicone gaskets) on all openings and ports. Choose speaker cones and surrounds made of waterproof materials (aluminum cones, rubber surrounds). Aim for a good IP rating: e.g. IPX7 means it can survive being briefly submerged. Properly sealing the enclosure and using corrosion-resistant screws/materials is key

Q: Why do some speakers have wood inside?

A: Some speaker boxes use wood for internal braces or panels because wood adds rigidity and dampens vibrations. Baltic birch plywood, for example, is very stiff yet light. It helps the speaker sound better by reducing resonance inside the box When sealed and finished, the wood also protects from dust and moisture.

Q: What is IP67 rating for speakers?

A: IP67 means the speaker is dust-tight (6) and waterproof up to 1 meter for 30 minutes (7). This requires high-quality seals and materials. According to MISCO, a speaker with a rubber (NBR) surround and aluminum cone can achieve IP67 if the enclosure is properly sealedIn practice, an IP67 Bluetooth speaker can survive rain, splashes, and even accidental drops into water without damage.

Q: Can I use silicone to protect my speaker?

A: Yes, silicone is often used as a protective cover or coating. Silicone cases act like bumper guards to absorb impacts. Silicone gaskets around joints keep water out. It doesn’t corrode and stays flexible in heat/cold, making it ideal for weatherproofing. Many rugged speakers have silicone exteriors or grips for this reason

How to Build a High-Quality Bluetooth Speaker: A Step-by-Step DIY Guide Read More –>

One thought on “Best Materials for Building a Durable Bluetooth Speaker”